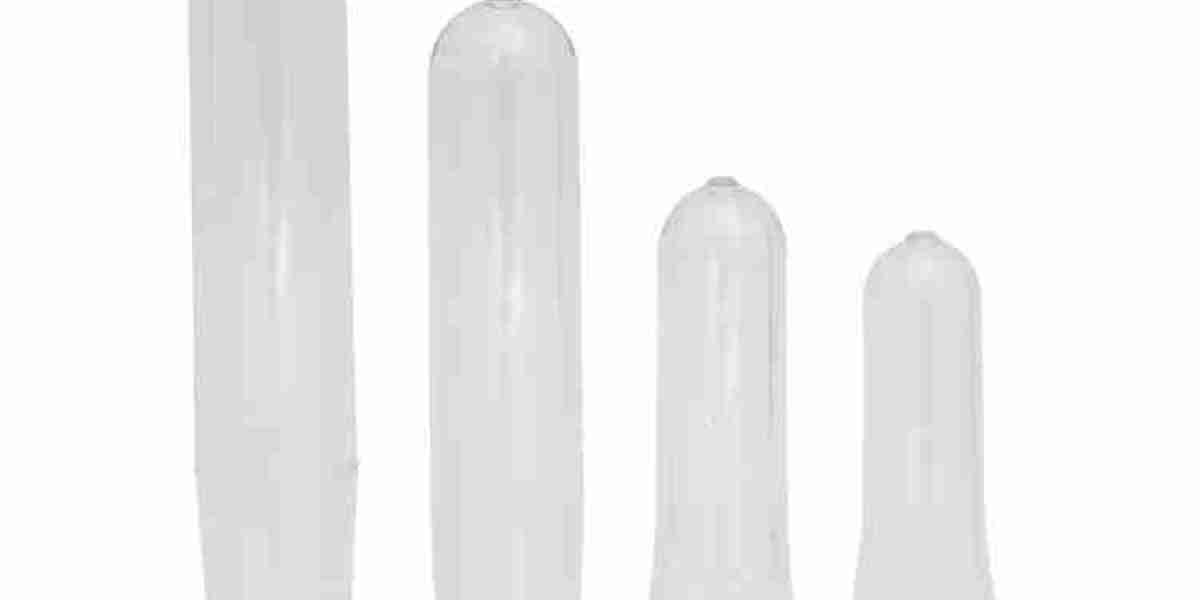

A PET preform is a tube-like piece of plastic, typically in the shape of a small bottle, that is molded through an injection molding process. These preforms are later heated and stretched into their final shape using a blow molding process. For 5-gallon containers, PET preforms are designed to be molded into large, rigid bottles that are often used for water, beverages, or other liquid products.

5-gallon PET preforms are specifically designed to withstand the stresses associated with large containers, including the pressure created by the contents, the weight of the liquid, and the handling requirements of the filled bottles. Choosing the right preform is essential to ensuring that the final 5-gallon bottle is strong, leak-proof, and fit for its intended purpose.

The quality of the PET material used for the preform is one of the most critical factors to consider. PET is a widely used material for bottle manufacturing because of its high strength-to-weight ratio, good chemical resistance, and excellent transparency. However, not all PET is created equal. For 5-gallon bottles, it is important to choose PET material that has been specifically formulated for larger containers, as it must be able to withstand the increased stress and pressure that comes with the volume of liquid being stored.

High-quality PET preforms typically have a higher molecular weight, which enhances the material's durability, rigidity, and resistance to cracking. Additionally, PET with improved barrier properties can help prevent the degradation of the contents, particularly for beverages or products that are sensitive to light, oxygen, or carbon dioxide.

The weight and thickness of the PET preform directly affect the strength and durability of the final 5-gallon bottle. A preform that is too thin may result in a bottle that is prone to cracking, leaking, or warping under pressure. Conversely, a preform that is too thick could lead to unnecessary material waste and increased production costs.