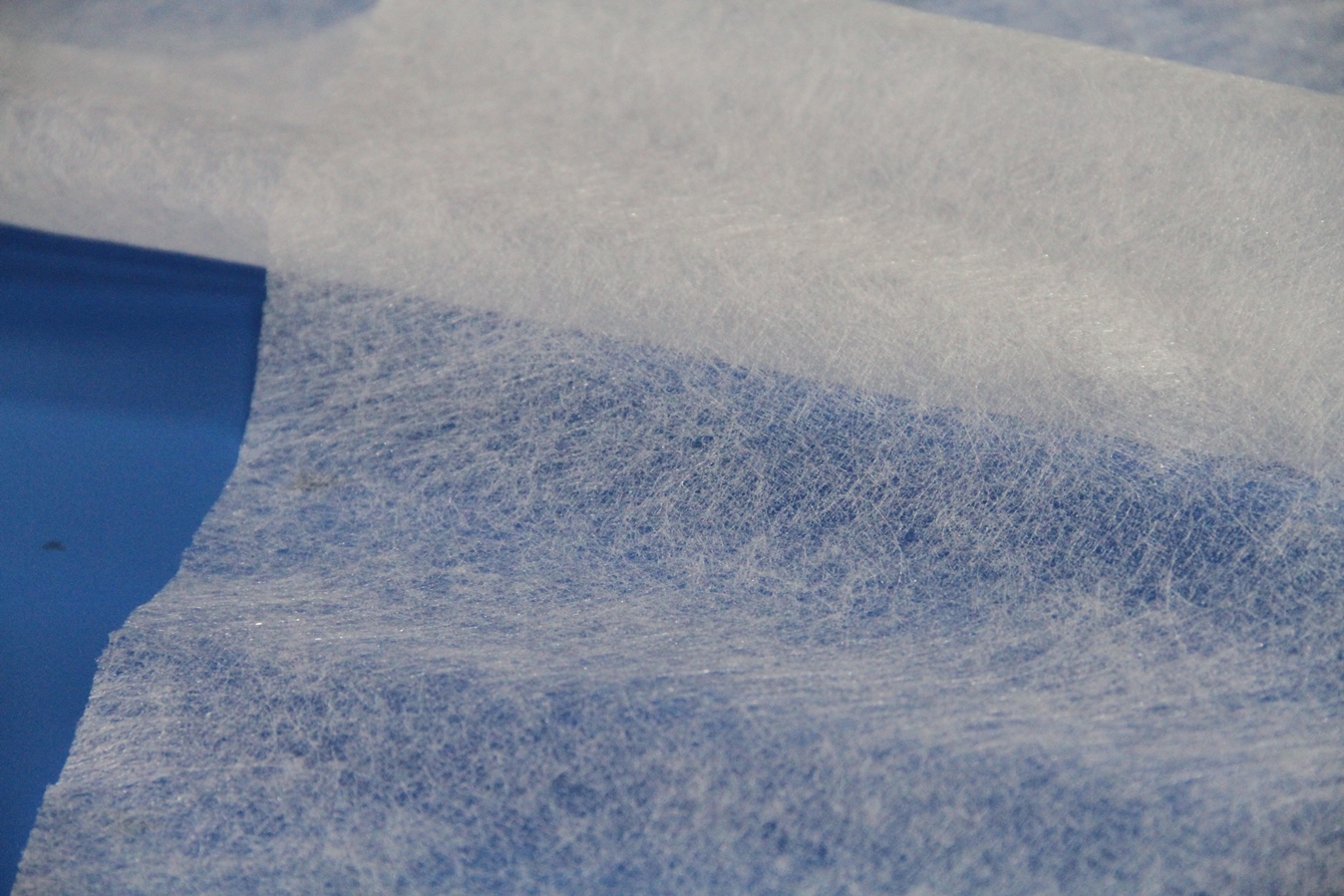

The polyester hot-melt adhesive web is a versatile and reliable adhesive that possesses many benefits and applications across a wide variety of different industrial sectors. Because of its one-of-a-kind properties, such as its resistance to high temperatures, exceptional bonding strength, and good flexibility, it is ideally suited for bonding a wide variety of materials. Polyester PES hot melt double sided adhesive lining is an option for an adhesive that is both cost-effective and environmentally friendly, and it is one that should be considered for the fulfillment of industrial adhesive requirements because of the many advantages it offers and the diverse fields in which it can be applied. Manufacturers are able to select the appropriate polyester PES hot melt double sided adhesive lining for the specific application requirements they have by first gaining an understanding of the material's characteristics, applications, and benefits, and then taking into consideration the factors involved in selecting the appropriate adhesive.

When Choosing Polyester PES Hot Melt Double Sided Adhesive Lining, There Are a Few Things You Should Keep in Mind:

Several aspects need to be taken into consideration before deciding on the polyester PES hot melt double sided adhesive lining that will be used for a specific application. These factors are as follows:

Material compatibility: the Polyester PES hot melt double sided adhesive lining might not form a strong bond with certain materials, such as fluorocarbons and polyolefins. As a result, it is absolutely necessary to think about whether or not the adhesive and the materials that are going to be bonded are compatible with one another.

Temperature required for activation The temperature required for activation of polyester PES hot melt double sided adhesive lining varies depending on the type of adhesive used. It is absolutely necessary to choose an adhesive with an activation temperature that is appropriate for the components that are going to be bonded together.

The bonding strength of polyester PES hot melt double sided adhesive lining can vary depending on the type of adhesive used and the materials that are being bonded together. It is of the utmost importance to choose an adhesive that possesses the level of bonding strength that is suitable for the task at hand.

Environmental factors: When selecting pes hot melt double sided adhesive lining, it is important to take into consideration the environment in which the bonded materials will be used. The performance of the adhesive can be impacted by a variety of factors, including temperature, humidity, and proximity to chemical sources.

When selecting polyester PES hot melt double sided adhesive lining, the production process is another factor that needs to be taken into consideration. The selection of the adhesive can be influenced by a variety of factors, including the speed of production, the properties of the adhesive that are required, and the equipment that is readily available.

Applications for Polyester PES Hot Melt Double Sided Adhesive Lining Polyester PES hot melt double sided adhesive lining has a wide range of applications across a number of different industries.

The following are some examples of frequent applications:

Bonding textiles: Polyester PES hot melt double sided adhesive lining is a type of adhesive that sees extensive use in the textile industry for the purpose of bonding fabrics, non-woven materials, and laminates. It provides a strong and long-lasting bond that can withstand being washed and cleaned with dry chemicals.

Bonding footwear: Polyester PES hot melt double sided adhesive lining is used in the manufacturing of footwear for bonding shoe uppers, linings, and insoles. This occurs during the bonding step of the production process. Because of its flexibility and its strong bond, the components of the shoe will remain bonded even when subjected to harsh conditions.

Bonding in the automotive industry: Polyester PES hot melt double sided adhesive lining is used in the automotive industry for bonding interior and exterior trim components, such as door panels, headliners, and carpets. This adhesive lining is used for bonding in the automotive industry. Because of its resistance to both high temperatures and chemicals, it is ideally suited for use in the demanding environments that are found in vehicles.

Bonding in electronics: Polyester PES hot melt double sided adhesive lining is used for bonding components in the electronics industry, such as touch screens and displays. Because of its resistance to high temperatures and its exceptional bonding strength, it is an excellent material for use in the production of electronic devices.

The medical device industry makes extensive use of polyester PES hot melt double sided adhesive lining for bonding components like electrodes and sensors together. Because of its high bonding strength, excellent biocompatibility, and good flexibility, it is an ideal adhesive for use in medical devices.

OrlandoOrtiz

3 Blog Postagens