Precision Custom Shaft Manufacturing: Understanding the Process Techniques and Industrial Applications

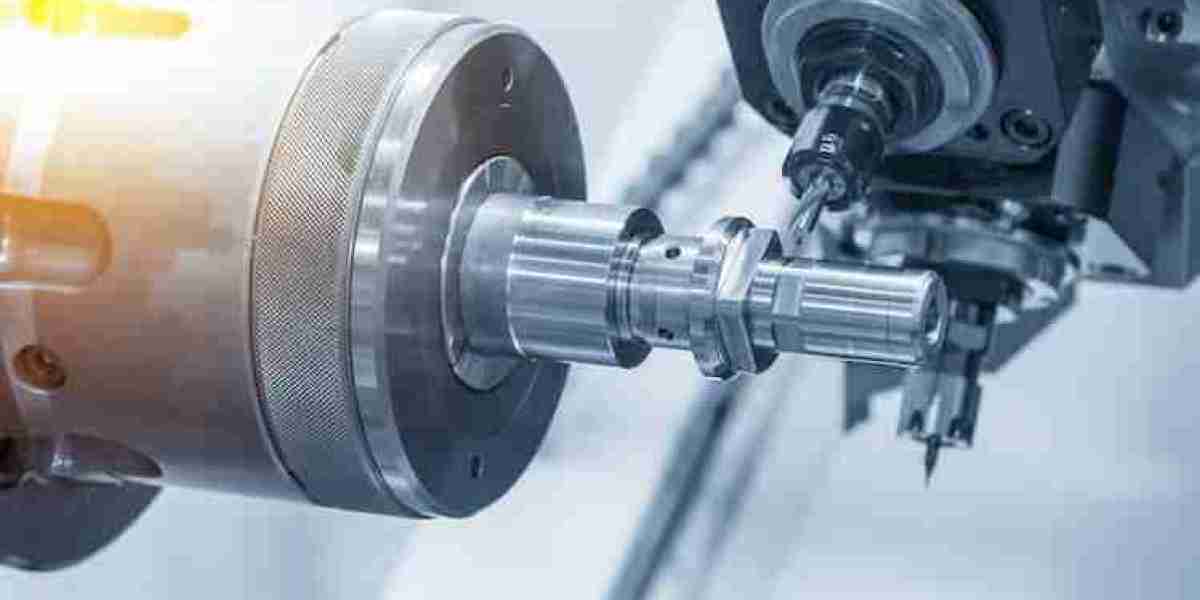

A shaft is a vital cylindrical component that transfers rotational motion and torque within machinery. From small motors to large industrial equipment, precision cylindrical shafts are essential mechanical parts. However, manufacturing custom shafts to meet the precise specifications and quality standards of various industrial applications can be challenging. This article discusses the techniques, materials, and surface finishing options involved in precision custom shaft manufacturing. It also explores some key industrial applications that benefit from custom shaft manufacturing.

Table of Contents

- Understanding Custom Shaft Manufacturing

- Key Machining Techniques

- Materials for Custom Shafts

- Surface Finishing Options

- Industrial Applications of Custom Shafts

- Conclusion

Understanding Custom Shaft Manufacturing

Custom shaft manufacturing involves designing shaft components to precise specifications, creating CAD models, generating CNC toolpaths, machining the shafts on CNC machines, and applying suitable surface treatments. Several factors must be considered, such as the intended application, operating environment, required tolerances, and design loads.

The process typically begins with discussing the project requirements with engineering teams to understand the design parameters. An experienced CAD designer then models the custom shaft geometry. CAD data is converted into G-code using CAM software. CNC turning, milling, and drilling then shape the shaft blanks as per the programmed toolpaths.

Quality checks ensure dimensional accuracy before any finishing steps. Surface treatments help optimize properties like wear/corrosion resistance. Proper planning and技 manufacturing techniques are crucial to produce shafts meeting critical industrial standards.

Key Machining Techniques

Several specialized machining techniques are used to shape custom shafts with tight tolerances:

CNC Turning: Ideal for basic cylindrical forms, CNC lathes spin the workpiece against tools, removing excess material in a single set-up.

CNC Milling: CNC milling cutters machine flats, slots, keyways and other complex features on shaft surfaces.

CNC Grinding: Grinding wheels delicately remove minimal material for extremely fine surface finishes and dimensions.

CNC Drilling: Drill tiny holes and channels with precision, suitable for oil/coolant passages.

EDM: Electrical discharge machining shapes hard metals by electric sparking, suitable for intricate internal details.

Selecting the right machining approach based on part geometry and material helps achieve the required specifications for industrial shaft components.

Materials for Custom Shafts

Common materials used in custom shaft manufacturing include:

Carbon Steel: Applicable for general-purpose shafts with excellent machinability.

Alloy Steel: High-strength option suited to heavy-duty applications.

Stainless Steel: Corrosion-resistant for chemically aggressive environments.

Aluminum: Lightweight material preferred where weight savings are critical.

Titanium: Heat and corrosion resistant, used in aerospace and medical industries.

Plastic: Self-lubricating, non-corroding alternatives for specific applications.

Selecting the right material balances critical factors like strength, weight, corrosion resistance as per industrial needs.

Surface Finishing Options

Additional surface treatments enhance shaft properties and functionality:

Passivation: Protects stainless steel from corrosion with a passive oxide layer.

Anodizing: Increases hardness and corrosion resistance of aluminum.

Plating: Deposits like chrome improve wear/corrosion resistance.

Polishing: Results in a smoother, highly reflective, contamination-resistant finish.

Peening: Compressive stress treatment increases fatigue strength.

Proper finishing is essential for industrial shafts facing extreme environments.

Industrial Applications of Custom Shafts

Custom shaft manufacturing benefits various industries including:

Automotive: Engine, transmission and steering components require high-precision Shafts.

Industrial Machinery: Machines like cranes, Robotics and factory equipment rely on durable shafts.

Oil and Gas: Pumps, turbines and downhole components need corrosion-resistant shafts.

Aerospace: Aircraft engines, landing gear and flight control actuators require lightweight, high-grade shafts.

Medical Devices: Surgical tools, implants and diagnostics need biocompatible shafts.

3D Printing: Additive manufacturing machines utilize precision shafts for positioning components.

CNC Machining Services help manufacturers meet tight design specifications for shaft parts across industries.

Conclusion

Precision custom shaft manufacturing combines mechanical design expertise, advanced machining techniques, suitable materials selection and finishing. This ensures functional cylindrical parts with accuracies important for industrial systems. Proper planning considering application parameters is key to producing high-quality shaft components.

For more details on CNC Machining Services and shaft manufacturing capabilities, contact Diecasting-Mould today.