Ensuring Accurate Weighing for Industrial Operations: Calibration Methods for Truck Scales and Platform Scales

Introduction

Regular calibration of weighing equipment is crucial for industarial operations to ensure compliance with regulations and maintain precision. Whether weighing raw materials, finished goods, or trucks, accurate measurement is essential. As scales are exposed to varying environmental conditions, calibration ensures adjustments are made to account for any impacts on performance. This article examines calibration techniques for truck scales and platform scales commonly used by Bincen, a leading Chinese manufacturer.

Table of Contents

- Weight Calibration

- Dual-Axis Load Cell Calibration

- Corner Test Calibration

- Temperature Compensation

- Calibrating Platform Scales

Conclusion

Weight Calibration

Weight calibration is fundamental for truck scales and industrial platform scales. It involves applying certified test weights to load cells or sections of the weighing surface. Readings are compared to known weights, with adjustments made if discrepancies emerge. This ensures baseline accuracy before other calibration techniques.

Dual-Axis Load Cell Calibration

Truck scales typically use multiple load cells beneath the weighing surface. Dual-axis calibration evaluates each cell individually by applying weights to specific points. Readings are cross-checked to ensure consistency between cells. Any variation is adjusted to optimize overall scale performance.

Corner Test Calibration

Uneven loading could impact accuracy if not addressed. Corner testing places weights at each barrier or vehicle scale edge to check for uniformity across the entire surface. Adjustments rectify potential issues from off-center loads.

Temperature Compensation

Temperature profoundly influences strain gauge load cells. Sensors monitor fluctuations to enable compensation algorithms or adjustments preserving precision weighing under varying thermal conditions.

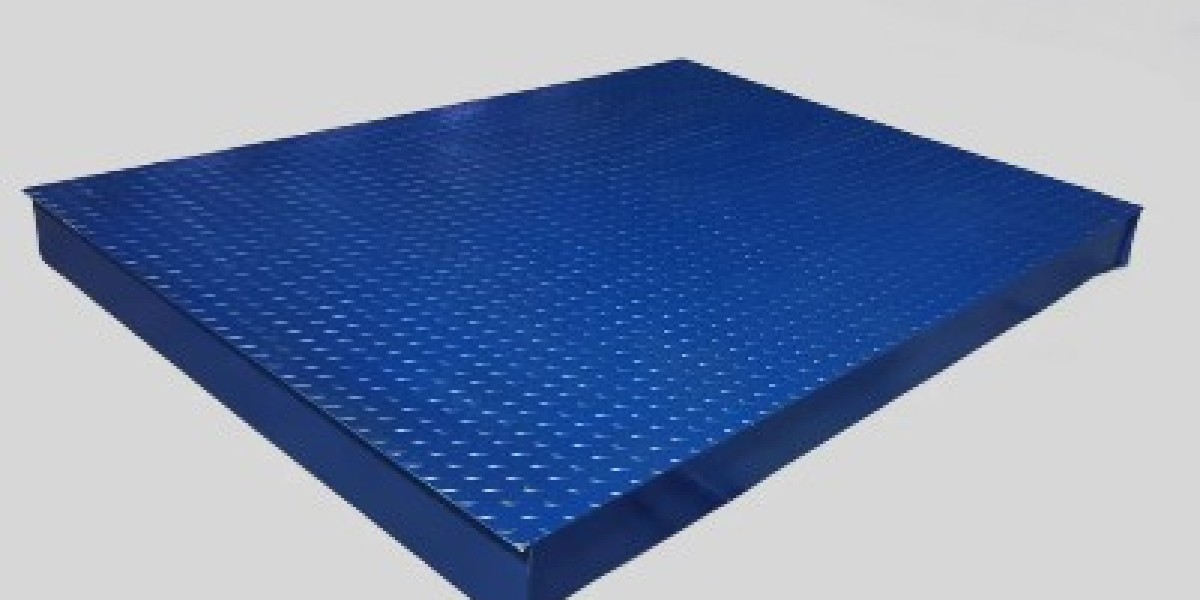

Calibrating Platform Scales

Platform scales like Bincen's double deck scale and small weighbridge scale apply the same principles. However, multiple or off-center load points simulate real use. Corner and dual-axis calibration ensure loads are equally distributed to connected load cells. Temperature compensation is also critical with platform scales inside facilities.

Conclusion

Regular calibration upholding these proven techniques maintains compliance and weighs confidence for operations. Seeking expertise from manufacturers like Bincen ensures scales continue serving industries precisely as conditions vary. Proper calibration safeguards productivity and protects budgets relying on industrial weighing.