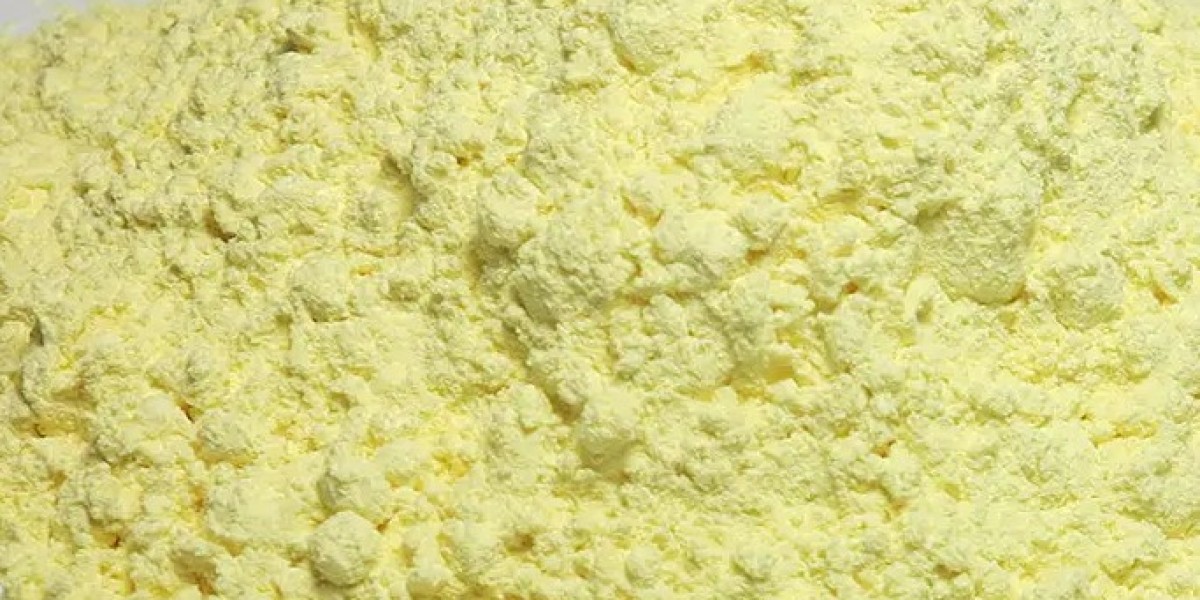

Melamine resin is a highly versatile material used in a variety of industries due to its unique combination of durability, resistance, and aesthetic appeal. This thermosetting plastic is created by polymerizing melamine and formaldehyde, resulting in a material that offers numerous benefits for manufacturers and end users alike. When compared to other materials, melamine resin stands out for its ability to combine strength with aesthetic qualities, making it a valuable asset across a wide range of applications.

One of the primary advantages of melamine resin is its exceptional hardness. Once cured, melamine resin forms a rigid, tough surface that resists scratching and abrasion. This characteristic makes it an ideal choice for furniture, flooring, and countertops, where longevity and durability are important. Products made from melamine resin are able to withstand heavy usage while maintaining their appearance over time, which is crucial for products in high-traffic areas.

In addition to its hardness, melamine resin is known for its excellent resistance to heat and chemicals. This makes it a popular choice for applications where exposure to high temperatures or harsh chemicals is a concern. For example, in the production of kitchenware such as dinnerware and trays, melamine resin provides a sturdy, heat-resistant surface that holds up well under normal daily use. It also resists staining from food and beverages, making it easier to maintain the appearance of products over time.

Another key benefit of melamine resin is its versatility in design and aesthetics. The resin can be produced in various colors and patterns, allowing manufacturers to create a wide range of visually appealing products. It is often used to create laminate surfaces that mimic the appearance of wood, stone, or other high-end materials, offering a cost-effective solution for interior design without sacrificing style. This ability to imitate more expensive materials helps manufacturers provide consumers with aesthetically pleasing products at a lower price point.

Melamine resin’s resistance to moisture is also a significant advantage in many applications. In the furniture and construction industries, melamine resin is used to coat surfaces that are exposed to varying levels of humidity, such as countertops and cabinetry. Its moisture resistance helps prevent warping and swelling, which can occur in wood and other materials when exposed to water over time. This makes melamine resin a preferred option in areas like kitchens and bathrooms, where moisture is common.

From an environmental perspective, melamine resin is a durable and long-lasting material, reducing the need for frequent replacements. Its resistance to wear and tear helps extend the lifecycle of products made with it, which in turn reduces waste and contributes to more sustainable manufacturing practices. Furthermore, melamine resin is a recyclable material, meaning that it can be repurposed at the end of its life cycle, reducing its environmental impact.

In conclusion, melamine resin offers several advantages that make it a valuable material in many industries. Its hardness, heat resistance, chemical durability, aesthetic versatility, and moisture resistance make it an ideal choice for products ranging from kitchenware to furniture and flooring. These qualities, combined with its ability to contribute to sustainable manufacturing, ensure that melamine resin remains an essential material in modern production processes.