Introduction to DTF Sheets

In the world of textile and garment printing, innovation is key to achieving high-quality, durable, and vibrant prints. One of the latest advancements in printing technology is the DTF sheet, which plays a crucial role in Direct to Film (DTF) printing. Whether you’re a professional printer or a DIY enthusiast, understanding DTF sheets can help you produce stunning prints with ease.

What is a DTF Sheet?

A DTF sheet is a specially coated film used in the Direct to Film printing process. It acts as a medium to transfer ink from a printer onto fabric or other materials. Unlike traditional printing methods, DTF printing does not require weeding or pretreatment, making it a more efficient and versatile solution for custom designs.

How DTF Printing Works

DTF printing involves a few key steps to achieve high-quality prints. Here’s how the process works:

Printing on the DTF Sheet

The design is printed in reverse on a PET (Polyethylene Terephthalate) DTF sheet using a specialized inkjet printer with DTF inks.

Applying the Adhesive Powder

After printing, a special DTF adhesive powder is applied to the printed design while the ink is still wet. This powder ensures proper adhesion to fabric.

Curing the Print

The sheet with the adhesive powder is then heated to cure the design. This step is crucial for durability and color vibrancy.

Transferring the Design to Fabric

The prepared DTF sheet is placed onto fabric, and heat is applied using a heat press machine. The ink and adhesive bond with the fabric fibers.

Peeling and Finishing

After pressing, the DTF sheet is peeled away, leaving a high-quality, long-lasting design on the fabric.

Benefits of Using DTF Sheets

DTF sheets offer several advantages over other printing methods:

Versatility: Works on a wide range of fabrics, including cotton, polyester, blends, and even leather.

Vibrant Colors: Produces high-resolution, bright, and detailed prints.

Durability: Resistant to washing, stretching, and fading.

Cost-Effective: Eliminates the need for expensive pretreatment solutions.

Easy Application: No need for cutting or weeding like vinyl printing.

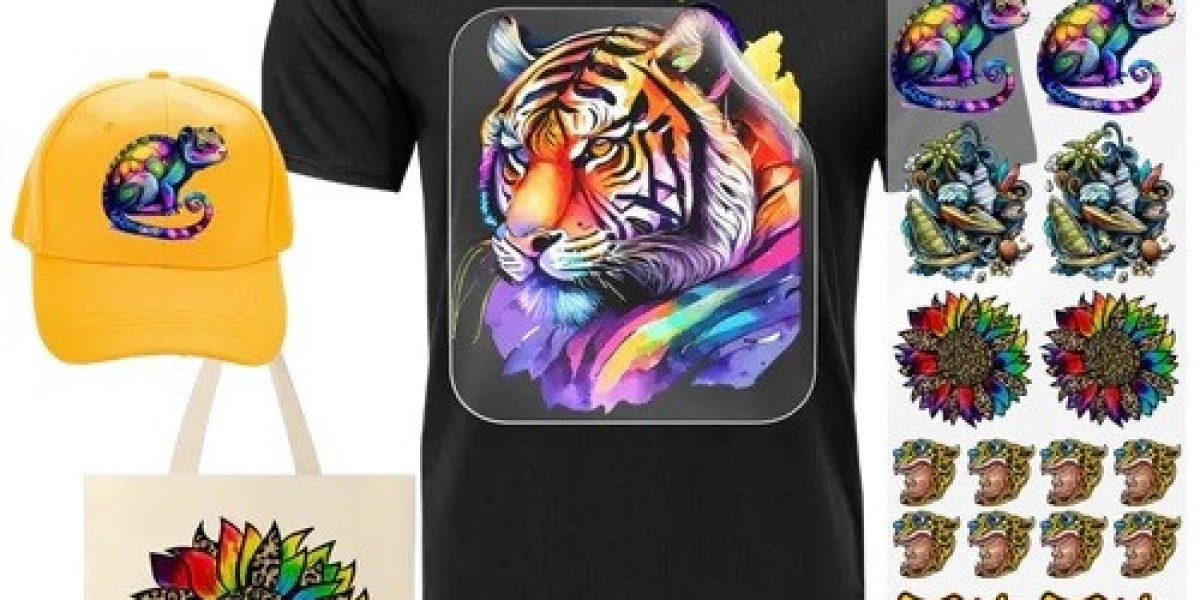

Applications of DTF Sheets

DTF sheets are widely used in various industries and applications, including:

Custom Apparel Printing: Ideal for t-shirts, hoodies, and sportswear.

Corporate Branding: Used for uniforms, promotional items, and branding merchandise.

Personalized Gifts: Enables custom designs on tote bags, caps, and home décor items.

Small Business & DIY Projects: Perfect for entrepreneurs looking to start a custom printing business.

Choosing the Right DTF Sheets

When selecting DTF sheets, consider the following factors:

Quality of PET Film: Look for sheets with a smooth, even coating for better ink absorption.

Compatibility with Printers: Ensure the sheets work with DTF-compatible printers and inks.

Size and Thickness: Choose the appropriate dimensions based on your printing needs.

Heat Resistance: Opt for sheets that can withstand high temperatures without warping.

Tips for Successful DTF Printing

To achieve the best results with DTF sheets, follow these tips:

Use High-Quality Inks and Powders – Investing in premium DTF inks and adhesive powders ensures better print quality and durability.

Maintain Proper Temperature and Pressure – Follow manufacturer recommendations for heat press settings.

Store Sheets in a Cool, Dry Place – Prevent moisture damage by keeping DTF sheets in a controlled environment.

Test Before Bulk Printing – Always perform a sample print to check for color accuracy and adhesion quality.

Conclusion

DTF sheets are revolutionizing the printing industry by offering a simple yet highly effective way to transfer designs onto various materials. Whether you’re looking to create custom clothing, promotional items, or unique gifts, DTF printing provides a durable and high-quality solution. With the right equipment and techniques, you can achieve professional-grade prints that stand the test of time.

Embrace the future of printing with DTF sheets and unlock endless creative possibilities!