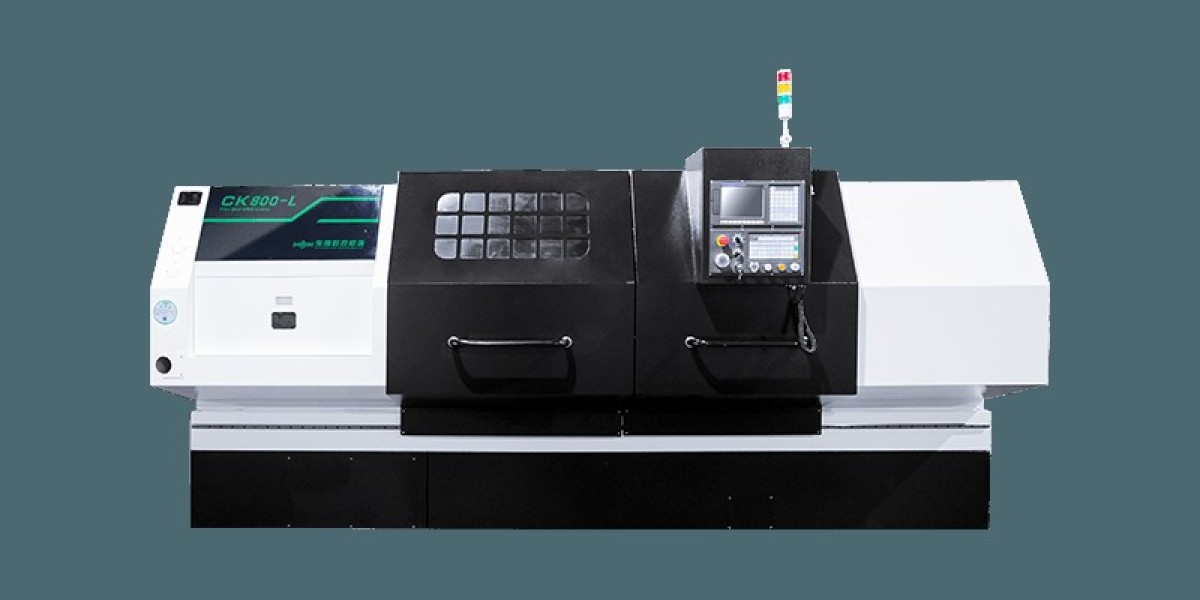

In the ever-evolving world of manufacturing, the ability to produce high-quality, accurate parts quickly and efficiently is crucial. This is where the CNC Flat Bed lathe comes into play. By combining the tried-and-true principles of traditional lathes with modern CNC technology, these machines provide an essential tool for producing precision parts across a variety of industries.

The flat bed design of these lathes sets them apart from conventional machines. This sturdy and rigid structure is ideal for handling large, heavy workpieces, making it especially useful for industries that require complex, large-scale machining. The flat bed's stability ensures that the workpiece remains secure, minimizing vibrations that could affect machining accuracy. As a result, CNC flat bed lathes are capable of achieving tight tolerances, even with demanding materials such as steel and other tough metals.

One of the key features of CNC flat bed lathes is their flexibility. These machines are capable of executing a wide range of machining operations, including turning, threading, boring, and drilling. This makes them highly versatile and suitable for producing a variety of components, from automotive parts to aerospace components. With the ability to easily switch between different tasks, manufacturers can streamline their production processes and reduce the need for multiple machines.

In addition to their versatility, CNC flat bed lathes also offer increased productivity. By automating many of the machining processes, these machines allow for faster production cycles. With pre-programmed commands and automated processes, operators can significantly reduce the time spent on setup and manual adjustments. This enhanced automation also minimizes the chances of human error, ensuring a consistent level of quality across each part produced.

The precision and repeatability offered by CNC flat bed lathes are among their most significant advantages. Unlike manual lathes, which are heavily reliant on operator skill, CNC flat bed lathes can produce identical parts with minimal variation. This is especially important in industries like medical device manufacturing or electronics, where precision is critical. CNC programming allows for exact replication of designs, ensuring that parts are made to the highest standards every time.

The integration of CNC technology also brings the benefit of user-friendly interfaces. The programming systems of CNC flat bed lathes are designed to simplify the process, allowing operators to create and modify machining programs quickly. This reduces training time for new operators and enables manufacturers to adapt to changing production requirements more easily.

Ultimately, CNC flat bed lathes offer a reliable solution for manufacturers seeking to enhance their machining capabilities. By combining precision, automation, and versatility, these machines are essential for companies that need to produce high-quality parts efficiently. As manufacturing demands continue to grow, the role of CNC flat bed lathes in meeting those needs will only become more prominent.