As the automotive industry continues to evolve, the demand for more complex and durable parts has significantly increased. In this context, the use of quality moulds such as Automotive Parts Mould becomes crucial in ensuring that automotive components are not only functional but also meet aesthetic and engineering specifications.

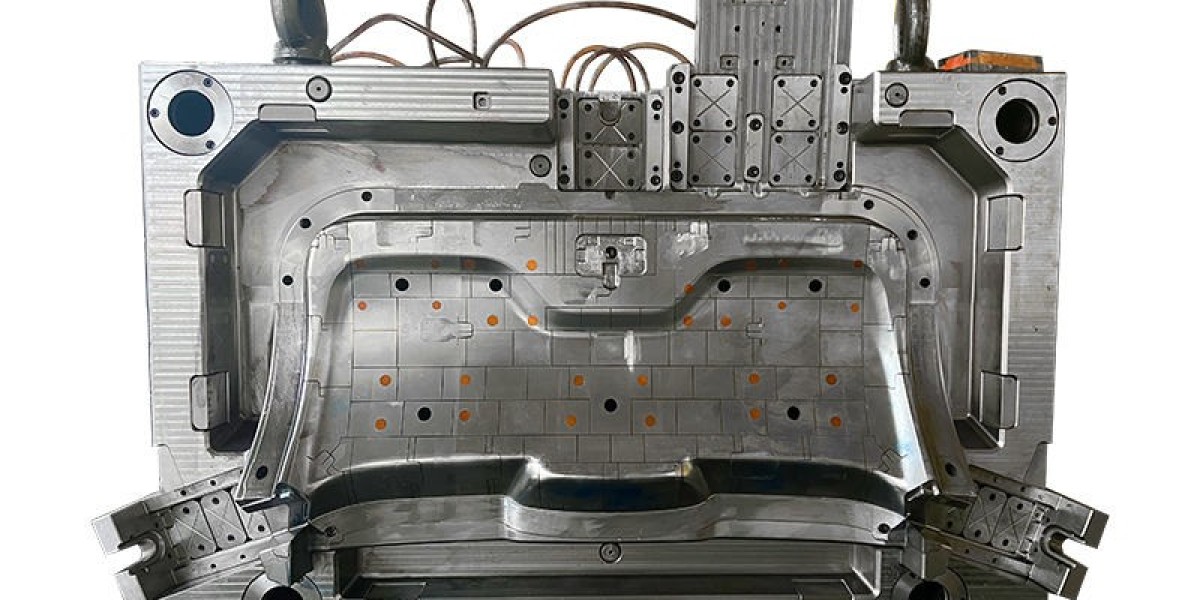

One of the most significant challenges in automotive manufacturing is achieving design precision. Parts need to fit together seamlessly, both in terms of mechanical function and aesthetic appearance. Automotive parts moulds are designed to provide this level of accuracy. With advanced injection moulding techniques, manufacturers can create parts that meet the tight tolerances required for modern vehicles, whether for engine components, interior features, or body panels.

Moreover, automotive parts moulds help reduce the margin for error. Once the design of the mould is perfected, the production process becomes more predictable and efficient. This allows manufacturers to avoid costly mistakes and reduce the need for manual intervention or reworking, which can be time-consuming and expensive. The precision provided by quality moulds also results in a more consistent final product, improving overall vehicle quality.

In addition to precision, the materials used in automotive parts moulds contribute to the overall durability of the parts. The moulds are designed to endure the high pressures and temperatures associated with the injection process, allowing them to produce parts that will hold up well over time. This is critical in the automotive sector, where parts must meet both safety and longevity standards.

By investing in high-quality Automotive Parts Mould, manufacturers can ensure that the components produced are of superior quality, accurate in design, and ready for use in vehicles that perform well under various conditions. The role of these moulds is key in driving innovation in automotive manufacturing.