Car bumper molding is a critical process in the manufacturing of automotive bumpers, shaping both their appearance and functionality. The bumper molding process involves creating the outer shell of the bumper using molds to form the required shape, which is then used in vehicle assembly. This process ensures that bumpers are manufactured with precision and consistency, meeting both safety and aesthetic standards.

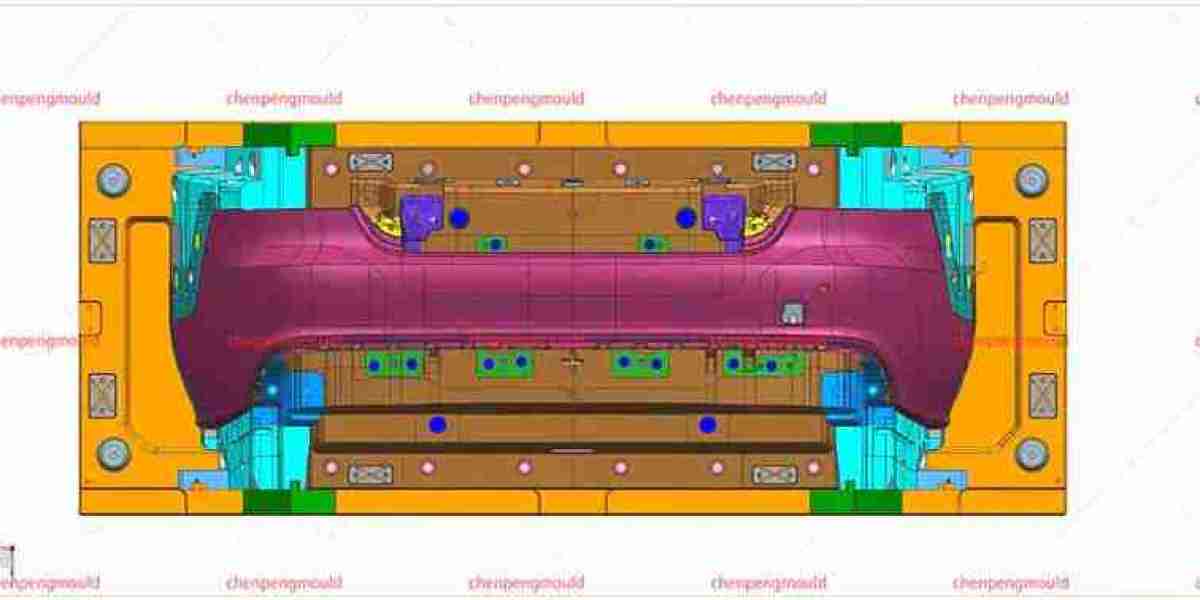

Bumper molds are typically made from durable materials like steel or aluminum to withstand the high temperatures and pressures of the molding process. In the molding process, materials such as thermoplastics or polypropylene are injected into the mold cavity, where they cool and harden into the desired bumper shape.

Car bumper molding plays a significant role in safety, as bumpers are designed to absorb impact in collisions, minimizing damage to the vehicle and protecting passengers. Additionally, the design of the bumper can enhance the vehicle's overall appearance, offering a smooth, sleek look that complements the car's style. Bumper molding is also crucial for integrating other features such as sensors, grilles, or lights.

Manufacturers must carefully choose the right mold for the production of bumpers, considering factors like material type, mold complexity, and production volume. Whether for mass production or custom designs, car bumper molding is a key part of creating high-quality, durable bumpers that fulfill both functional and aesthetic needs in modern vehicles.