Waterproof trunking is a specialized method of cable management that was developed as a solution to protect electrical cables from being damaged by water. This solution comes in the form of waterproof trunking. It is made up of long-lasting opinions or ducts that enclose, organize, and provide a watertight seal for the cables while also protecting them from the elements. Additionally, it shields the cables from the environment. The primary purpose of waterproof trunking is to provide protection for cables in areas where there is a possibility that they will come into contact with water.

Outdoor installations, industrial facilities, and other environments that are prone to moisture are some examples of the types of places that fall into this category.

The ability of waterproof trunking to prevent water ingress, which can lead to corrosion, short circuits, and electrical failures, is one of the most important features of this type of trunking. Other important features include the ability to prevent short circuits and electrical failures. Because it creates a barrier that is completely sealed around the cables, Waterproof trunking can ensure the reliability and longevity of the electrical system. This is because the trunking protects the cables from moisture and dust. In addition to this, it offers a number of benefits that cannot be found in other, more traditional approaches to cable management.

When compared to other kinds of cable trays and conduits, Waterproof trunking provides an exceptional level of defense against the risks associated with the presence of water. It eliminates the possibility of water penetrating the cables, which could compromise either their ability to conduct electricity or their insulation. In settings where there is frequent contact with water or where electrical equipment must function in damp or humid conditions, this is of the utmost significance.

The use of waterproof trunking makes both the maintenance and organization of cables much simpler and easier to perform.

It makes it possible to route cables in a neat and organized manner, thereby lowering the likelihood of tangles or other forms of accidental damage being caused by the cables. In addition to this, it makes it simpler to implement any future expansions or modifications by providing a pathway that is both flexible and easily accessible for the purpose of adding or replacing cables. This makes it possible to add or replace cables without much difficulty.

When searching for waterproof trunking, it is imperative to take into consideration the specific requirements of the application as well as the environment in which it will be installed. There is a choice of watertight trunking available, including both metallic and non-metallic varieties, which can be put to a number of different uses.

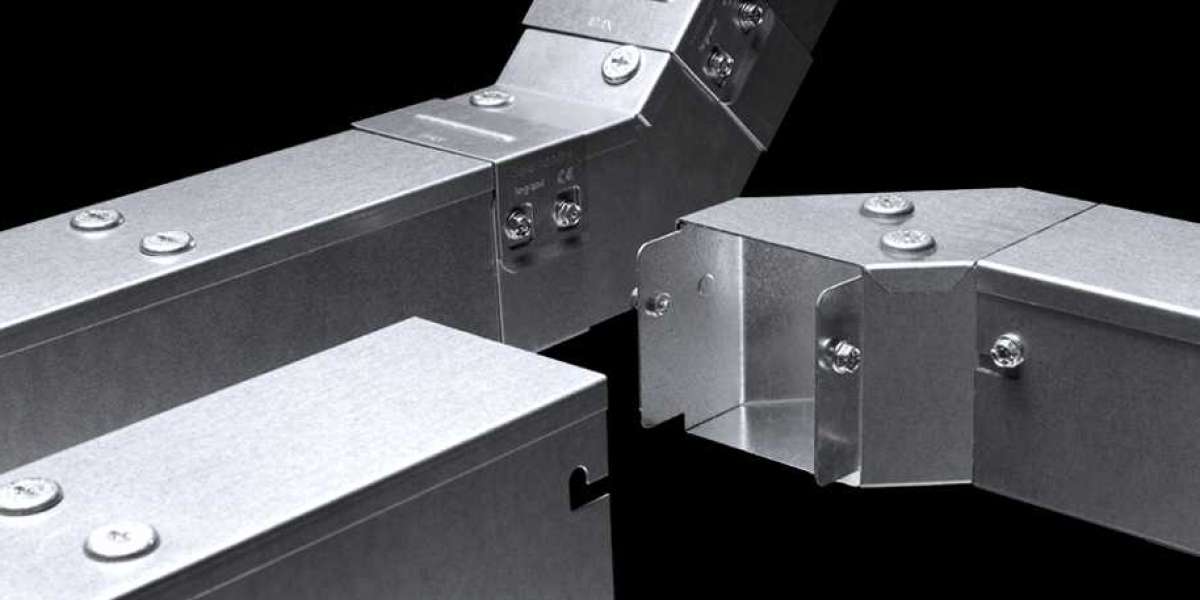

Metallic waterproof trunking is a type of trunking that is typically constructed out of materials such as galvanized or stainless steel. The term "metallic waterproof trunking" refers to this type of trunking. It has exceptional durability, mechanical strength, and resistance to impact, among other desirable qualities, and it is also resistant to other types of damage. Metallic trunking is an excellent choice for challenging environments that call for robust cable protection, such as those found in industrial facilities or outdoor installations that are subjected to harsh climatic conditions. These kinds of environments can be found in places like the United States.

On the other hand, non-metallic waterproof trunking is typically crafted from materials like PVC (Polyvinyl Chloride), fiberglass, or other synthetics with comparable properties. It provides an exceptional degree of defense against oxidation, chemical assault, and ultraviolet radiation. It is ideal to use lightweight, easy-to-maneuver non-metallic trunking because of its low weight and its convenience when electrical conductivity must be avoided in an installation, such as in an area with sensitive electronic equipment. This is because lightweight non-metallic trunking does not conduct electricity.

It is necessary to perform correct installation of the waterproof trunking as well as routine maintenance on it in order to ensure that it will function as intended and fulfill its purpose. During the process of installation, careful attention should be paid to ensure that the trunking is mounted securely, that sections are joined using fittings that are compatible with one another, that connections are sealed using the appropriate seals or gaskets, and that grounding measures are incorporated when they are required. All of these steps should be carried out in order to ensure that the trunking is installed correctly.

Routine inspections should be carried out so that any damage or signs of wear can be located; the trunking should be cleaned so that any debris or contaminants can be removed; and any maintenance issues should be resolved as soon as humanly possible. By adhering to best practices for installation and maintenance of their cable management systems, businesses, commercial spaces, and residential areas can all ensure the safety, longevity, and effectiveness of their cable management systems.

To summarize, Waterproof trunking is a solution that is not only dependable but also effective when it comes to cable management in harsh environments. As a result of its ability to protect cables from being harmed by water, its capacity to simplify organization and maintenance, and its ability to meet the requirements of a wide variety of applications, it has become an essential component in the electrical systems that are in use today. Businesses and individuals can ensure the safety of their cable installations, as well as their efficiency and longevity, if they have an understanding of the benefits, types, and proper installation and maintenance practices of waterproof trunking. Waterproof trunking also helps ensure that the cables will last as long as possible.