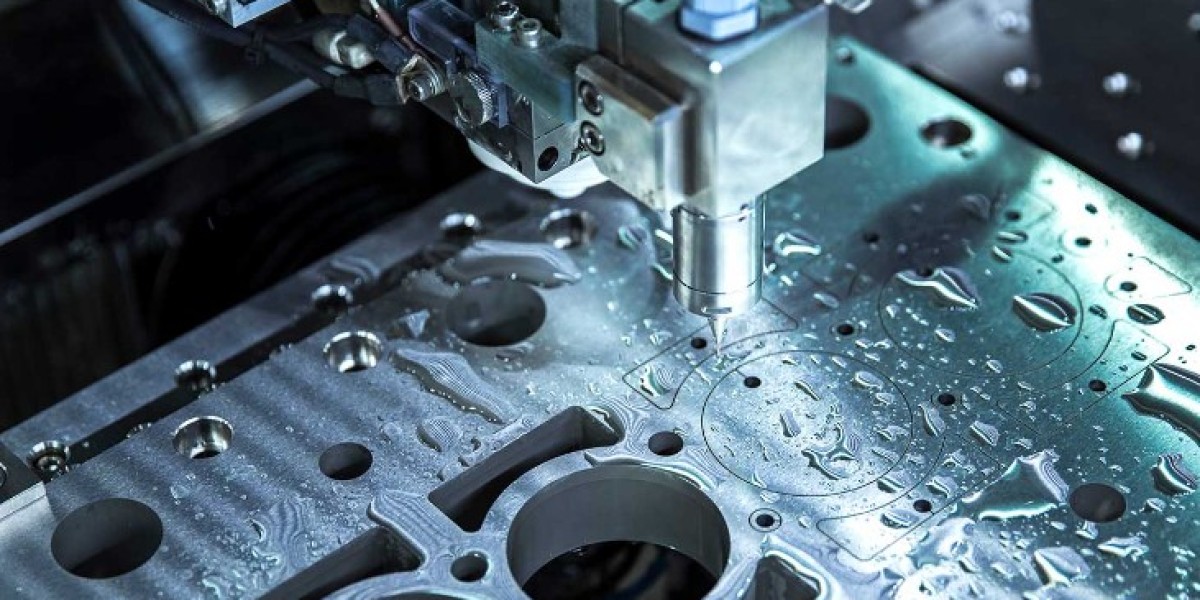

When designing parts for CNC machining, engineers often incorporate fillets and chamfers to enhance the aesthetics and functionality of their designs. While these features can improve the overall quality of the part, they also have a significant impact on the machining time and costs. In this article, we will explore the factors that contribute to increased machining costs when using fillets and chamfers and discuss strategies for optimizing designs to minimize expenses without compromising functionality.

Highlights:

- Understanding the impact of fillets and chamfers on CNC machining costs

- Factors contributing to increased machining time and expenses

- Design considerations for optimizing parts with fillets and chamfers

- Strategies for reducing machining costs without compromising functionality

The Function and Necessity of Fillets and Chamfers

Before incorporating fillets or chamfers into a design, it is crucial to consider their primary function and whether they are essential for the part's performance. While these features can enhance the appearance and eliminate sharp edges, they may not always be necessary for the part to function as intended. Engineers should also evaluate the cost-effectiveness of adding fillets and chamfers, particularly for low-volume production runs. The additional machining time required for these features can significantly impact the overall cost per part, making it essential to strike a balance between form and function.

The Challenges of Setting Up Tools for Fillets and Chamfers

Creating fillets and chamfers during the CNC machining process requires specialized tools, such as chamfer tools, corner rounding end mills, and ball-nose end mills. Setting up these tools can be time-consuming and expensive, as the cutter must blend the radius into the part's top and side faces without leaving any errors or steps. To achieve high-quality fillets, the cutter is programmed to closely follow the part edge and make very small step-overs, which increases the machining time and, consequently, the overall cost. As a result, engineers must carefully consider the necessity of each fillet and chamfer and weigh the benefits against the added expenses.

Production Volume and Its Impact on Machining Costs

The relationship between production volume and machining costs is another critical factor to consider when incorporating fillets and chamfers. Low production volumes typically result in higher costs per part, as the fixed costs of setting up the machines and tools are spread across fewer units. In contrast, large production runs may utilize casting or forging processes, where fillets and chamfers are not only cost-effective but also necessary for the part's performance. Engineers should carefully evaluate the production volume and select the most appropriate manufacturing method to optimize costs and functionality.

Designing Chamfers with Appropriate Tolerances

When designing chamfers, it is essential to specify the appropriate tolerances to minimize machining costs. Tighter tolerances require more frequent checks and specialized measurement tools, such as chamfer gauges, which can significantly increase the cost per part. By relaxing the tolerances within acceptable limits, engineers can reduce the need for frequent checks and allow the use of more common measurement tools, such as vernier calipers. This approach can help lower machining costs without compromising the part's functionality.

Simplifying Designs by Removing or Substituting Features

In some cases, removing chamfers entirely from the design can simplify the manufacturing process and reduce costs. If the exact size of the chamfer is not critical, engineers can opt to include a note on the drawing to "remove all sharp edges" or specify a minimum and maximum feature size with generous tolerances. When possible, substituting chamfers for fillets can also lead to cost savings. Chamfers along part edges are generally easier and more affordable to machine than fillets, as they require less setup time and fewer tool passes. If a fillet is necessary, using a standard size that can be created with a radius milling cutter can expedite the machining process compared to using a ball-nose end mill.

Leveraging Online Resources for Design Optimization

To gain a better understanding of how design decisions, such as incorporating fillets and chamfers, impact machining time and costs, engineers can take advantage of the wealth of online resources available. Websites like Engineer's Edge and Manufacturing Tomorrow offer valuable design tips and guidelines for optimizing parts for CNC machining. By staying informed about best practices and industry trends, engineers can make more informed decisions when designing parts with fillets and chamfers, ultimately leading to reduced machining costs and improved overall efficiency.

Conclusion

Fillets and chamfers play a crucial role in enhancing the aesthetics and functionality of CNC machined parts, but their impact on machining time and costs cannot be overlooked. By carefully considering the necessity of these features, optimizing designs with appropriate tolerances, and exploring alternative solutions, engineers can minimize machining expenses without sacrificing part performance. Leveraging online resources and staying abreast of industry best practices can further support engineers in making informed decisions and achieving optimal results in their CNC machining projects.